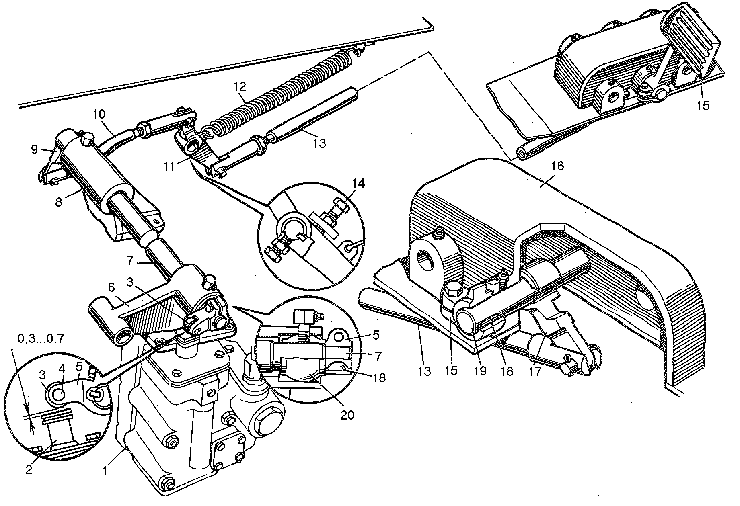

Clutch control meshanism

serves for controlling the clutch through the booster,also for driving the interlocking device of the gear shift forks.

The principal parts of the control mechanism are housing 16 mounted to the cab floor which encloses clutch pedal 15 keyed on shaft 19.

Lever 17 hinge-connected to tie 13 is fitted on shaft 19.The tie is connected to two-arm lever 11.The upper end of the latter is connected to tie 10 linked with lever 9 secured on shaft 7,which runs in two spherical bearings 20,mounted in brackets 6 and 8.Lever 5 with roller 3 fitted on axle 4 is secured on the other end of the shaft. When pedal 15 is depressed,the booster rod becomes actuated through the system of levers and ties and releases the clutch.When spring 12 returns the pedal into the initial position,the systems of levers and ties also return in the initial position.The booster rod occupies its initial position as well.The clutch becomes engaged.

To adjust the mechanism:

1) set lever 11 according to the marks on the lever and bracket 11, which corresponds to the interlocked position of the gearbox locks. When the clutch pedal is depressed,the locks should be unlocked,i.e. the fork shaft may move axially.When the interlock adjustment is impaired, gear shifting becomes difficult or impossible;

2) set a clearance between the roller and the booster rod surface within 0.3...0.7 mm (with the clutch pedal released).This clearance is necessary for providing the pedal free travel and preventing the rod seizure causing partial release of the clutch. Adjust by varying the length ot ties 10 and 13.

On completion of the tie adjuistment,check position of lever 11.This is required to ensure efficient operation of in interlocking of the gear shift shafts.