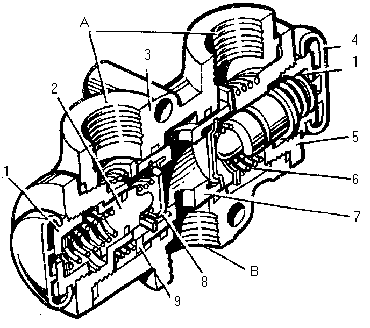

The double safety valve

The double safety valve is designed to disconnect the damaged circuit, aimed at keeping the other circuit under pressure.The double safety valve comprises body 3, two body covers 5, large piston 7, two small pistons 2, two valves 8, two plugs 1 and springs of large and small pistons.

Made in the body are three threaded holes for connecting the pipe unions of the pneumatic system: hole B, for connecting the intake union and two holes A, for connecting the unions of the circuits to be fed. Large piston 7, acting as a slide valve and having two valves 8, is mounted into the inside cylindrical cavity of the body. The piston under the action two springs 6 occupies the neutral position, when covers 5 are being screwed in.

When small pistons 2 are being set, valves 8 under the action of the springs are pressed to their seats formed by the piston butts.

Small pistons 2 move in the cylindrical holes of covers 5. When threaded plugs 1 are screwed into the covers, the pistons under the action of springs are pressed with their butts to the butts of the covers and occupy the fixed position. To adjust the beginning of the valves operating in case of failure of one of the circuits the adjusting gaskets are placed under the springs.

The holes are made in plugs 1 for communicating the cavity under the small piston with the atmosphere,when the small piston moves.

In the initial position large piston 7 under the action of springs 6 occupies the neutral position, spring valves 8 are pressed to their seats, small pistons 2 under the action of the springs are pressed to the cover butts. When air is fed from the compressor to intake hole B, the compressed air through the hole in large piston 7 actuates valves 8, presses them out their seats till they thrust against small piston 2, compresses the spring and enters through outlet holes A into the receivers of the individual circuits.

In case one of the circuits fails,pressure in the damaged circuit drops, large piston 7 under the action of pressure differential moves towards the damaged circuit, thrusting with its seat against valve 8, thus disconnecting hole B from the faulty circuit. Spring 6 of piston 7 is compressed at the end of the damaged circuit. The valve of the second circuit remains opened and air goes on flowing into the sound circuit. The double safety valve maintains pressure of the compressed air in the sound circuit within 0.52-0.55 MPa (5.2-5.5 kgf/cm 2) with the other circuit being faulty.

At an air pressure exceeding 0.55 MPa (5.5 kgf/cm2) the spring becomes compressed under the action of valve 8, the valve 8, the valve departs from the seat and a portion of air goes into the damaged circuit. After eliminating leakage, the faulty circuit becomes gradually filled with compressed air, pressure in the circuits equalizes, large piston 7 under the action of compressed spring 6 occupies intermediate position and the compressed air starts flowing again from intake hole B through outlet holes A into the receivers.