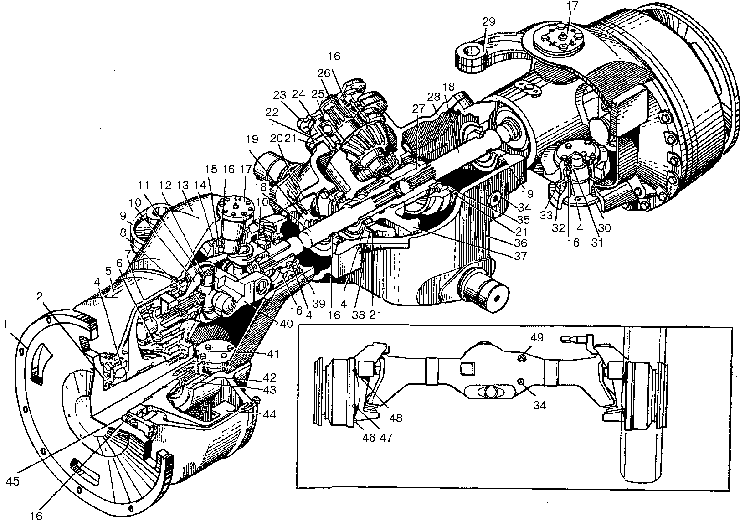

Front axle of motor grader DZ-98B

The front axle is driving and steerable. All its principal parts are similar to those of the rear and intermediate axles, except for the elements, ensuring steering of the wheels and fastening to the main frame.The cast heads are welded to the ends of the front axle cast beam.

1- hub;

2- sealing ring;

4- bearing;

5- final reduction gear housing;

6- insert;

7- pinion-shaft;

8,24,38, 41- bearing caps;

9,29- drag link fastening brackets;

10- universal-joint fork;

11- needle bearing;

12- universal-joint cross;

13- slewing bracket;

14,39,43- bearing housings;

15,32- gland housings;

16- collars;

17,30- pins;

18- axle-shaft;

19- collar housing;

20- locking screw;

21- adjusting gaskets;

22,33- sleeves;

23- flange;

25- oil baffle;

26- pinion-shaft;

27- bushing;

28- final drive bracket;

31- thrust bearing;

34- check plug;

35- cover;

36- beam;

37- bevel gear;

40- universal-joint intermediate link;

42- gasket;

44- drain plug;

45- bushing;

46- drain plug;

47,49 - filling hole plugs;

48-breather

In the middle portion of the beam along the motor grader longitudinal axis are located two pins arranged on one axis.The front axle is made to turn on these pins relative to the main frame in the transverse plane.

The axle shafts are of fully floating-type.The ends of the axle shafts receive the forks of the double Hooke's joint.This joint serves to transmit the torque to the final reduction gear,able to turn in the horizontal plane.The final reduction gears are similar to those installed on the rear axles, differing only in that they have no the wheel brakes and in that they are able to turn relative to the beam in the horizontal plane.They are interconnected by the steering gear tie rod used to adjust the toe-in of the front wheels.

The pins and cardan joint are lubricated through the grease cups according to "Lubrication Chart".