Lubrication system motor grader DZ-98B

All the components of lubrication system of the YAMZ-8482.10-01 engine are the engine accessories. Information of the design and the system operation on the whole as well as its components are presented in the engine technical descripton and operating instruction.The Y1D6-TK-C5 engine features a "dry" crankcase. For this reason the oil tank 1 is part of the engine lubrication system.

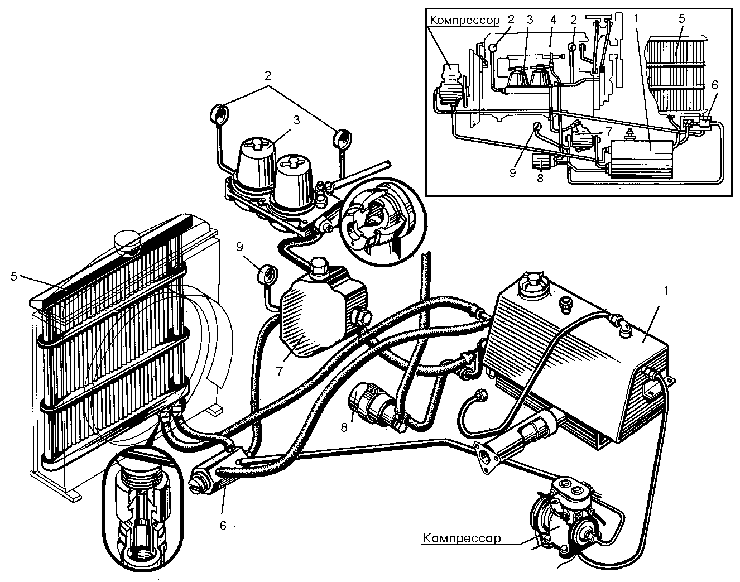

Another main com-ponents of the lubrication system are the engine oil pump 7, oil radiator 5, the reducing valve 6, the oil priming pump 8 and the piping system.

The oil tank is of welded design,featuring a fill-in throat, an oil dip stick, a drain cock. The tank is connected to the atmosphere via a breather of the engine crankcase.The tank is interconnected with the crankcase by a special foam-removing pipe. The breather packing should be periodically checked in the course of operation, since fouling results in the rise of pressure in the oil tank and the danger of tank deformation increases.

To ensure lubrication of the diesel engine friction parts before start-up (in order to decrease friction and prevent jamming), the oil main pipeline is pum-ped through with oil supplied under pressure by the oil priming pump. The oil used for this procedure is delivered by the oil-priming pump, which features a separate drive (the electric motor) whose operation is controlled with starter switch key.

The engine lubrication system functions as follows. During the pumping-through operation prior to engine starting,the oil is taken from the oil tank 1 is delivered via the pipeline by the oil-priming pump to the full-flow oil filter 3. Simultaneously the oil is fed to the engine stoppage device valve. On passing through the filter, the oil is delivered to the fan drive casing and therefrom-via the central seal-to the main pipeline of the engine. As soon as the oil pressure in the main pipeline rises up to 0.25 MPa (2.5 kgf/cm2) provision is made for lubrication of bearing and for actuating of the engine of the engine stoppage device valve. After the engine has been started, the delivery section of the oil pump 7 takes in the oil from the tank-via a pipeline -and delivers it to the oil is the oil filter 3.

After the filter, the oil is directed to the fan drive casing. In order to check the degree of the fouling of the filter 3,ahead of it into the delivery pipeline is fitted a pressure gauge 2. On more pressure gauge (of the same type) is fitted the filter 3. At a pressure difference exceeding 0.23 MPa (2.3 kgf/cm2), as shown by the pressure gauges, replace the filtering elements.The oil leaking from the points of lubrication is collected in the engine crankcase wherefrom it is delivered by the pumping-out section of the oil pump 7 to the pressure-reducing valve 6. From the pressure-reducing valve 6 the oil is partially fed to the compressor 1 of the pneumatic system for lubrication, whereas the remaining portion is drained-via the oil radiator 5 - to the oil tank.

To prevent damage to the oil radiator piping li-kely to result from a pressure rise produced by the cold oil,the pressure-reducing valve disconnect the oil radiator.To this end,the valve is present for a pressure of 0.08...0.13 MPa (0.8...1.3 kgf/cm2) which corresponds to the resistance of the radiator when the heated oil flows through it. If the oil is cold, it is fed from the engine directly the tank by-passing the radiator via the pipeline whose inlet hole opens as the pressure reducing valve gets released.

Caution! The engine starting is made possible only after the oil has been pumped through.

To prevent an accidental starting of the engine without prepumping of the oil, the engine fuel system features a special valve mounted upstream of the high-pressure fuel pump and permitting fuel supply to the pump only in case a pressure of oil not less than 0.25...0.3 MPa (2.5...3 kgf/cm2) is built up in the main oil pipeline. The lubrication systems of the YAMZ-240G, YAMZ-238HD3 and YAMZ-238HD2 engines are as follows:

1) the lubrication systems are manufactured on the principle of "wet" crancase, i.e. the oil tank is absent in the systems;

2) in the YAMZ-238HD3 and YAMZ-238HD2 engines is absent a oil-priming pump;

3) the oil pressure produced by the oil-priming pump prior to the YAMZ-240G engine starting should be not less than 0.1 MPa (1 kgf/cm2).