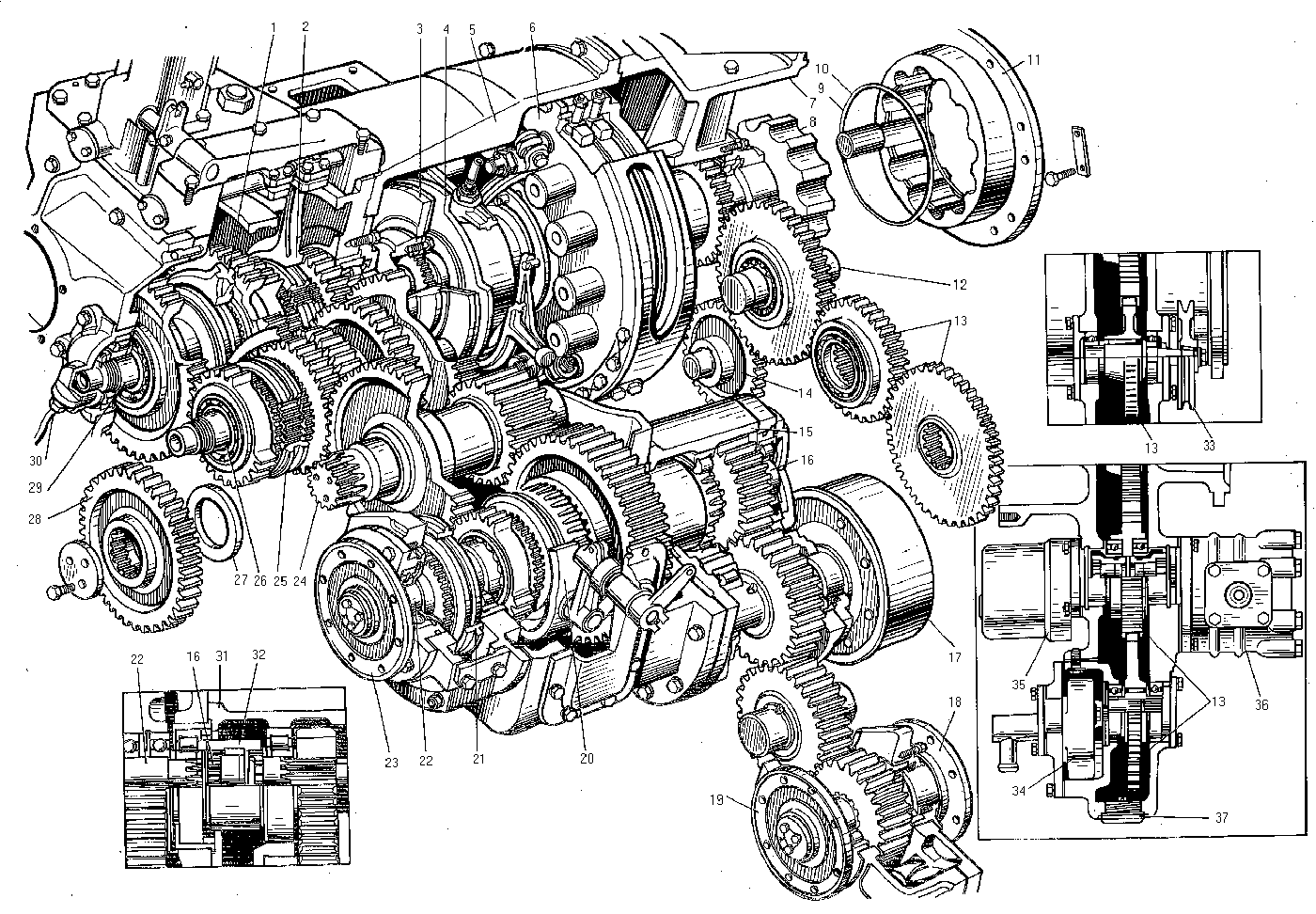

Power transmission motor grader DZ-98B

The power transmission is designed to transmit the torque from the engine to the driving wheels of the motor grader and makes possible to vary the value and direction of this torque,also to disengage the engine from the driving wheels. Besides,the transmission servers for taking off power to the drive of the hydraulic pumps. The power trans-mission icludes:

1) reduction gear of hydraulic pump drive;

2) clutch;

3) gearbox;

4) transfer reduction gear;

5) parking brake;

6) cardan transmission of the front axle drive;

7) cardan transmission of the intermediate and rear axle drive;

The reduction gear of the hydraulic pump drive,clutch, gearbox, transfer reduction gear and parking brake are combined in a unit,hereinafter refered to as "the transmission unit". The latter is connected to the engine flywheel housing by means of a centering bead made on the housing of the reduction gear of the hydraulic pump drive. No additional alignment is required.

The torque is transmitted from the engine to the transmission through a special flexible coupling which consists of the external coupling member, twelve rubber pins, spring rings and internal coupling member.

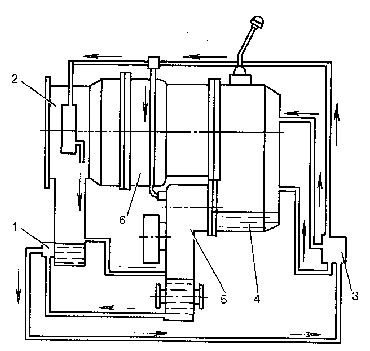

Lubrication of the transmission unit is of the combined type.

The schematic lubrication diagram is given in Fig.

Oil is primed into gearbox 4 and transfer reduction gear 5 through a filler neck located on top of the gearbox housing at the I.h. side in the direction of the motor grader travel,while into re-duction gear 2 of the hudraulic pump drive, through a filler neck located on top of the housing.

Oil is primed into gearbox 4 and transfer reduction gear 5 through a filler neck located on top of the gearbox housing at the I.h. side in the direction of the motor grader travel,while into re-duction gear 2 of the hudraulic pump drive, through a filler neck located on top of the housing.

Oil flowing from the gearbox housing enters the transfer reduction gear reservoir through the communicating ports. The latter are arranged so that a definite level of oil is ensured in the gearbox,transfer reduction gear and reduction gear of hydraulic pump drive.In the transmission unit the oil level is checked through the check plug of the transfer reduction gear.This is the only plug for checking the level of lubricant in the transmission unit.The oil baths in the housing of the reduction gear of the hydraulic pump drive,gearbox and transfer reduction gear serve for lubricating the parts of these mechanisms by splashing during rotation of gears.A forced lubrication is provided to lubricate the important parts to which simple splashing is difficult. Oil is fed by pump 1 whose suction line is connected to the intake,screwed into the transfer reduction gear housing,while the delivery line is connected to cross-piece 3.

The cross-piece is attached to the gearbox cover in its front portion. One pipeline is connected from the cross-piece to the filler neck of the pump drive reduction gear,while,two pipelines are connected to the covers closing the ends of the gearbox shafts.The oil pipeline for lubrication of the top bearing of the transfer reduction gear is tapped from the oil pipeline running to the reduction gear of the hydraulic pump drive.