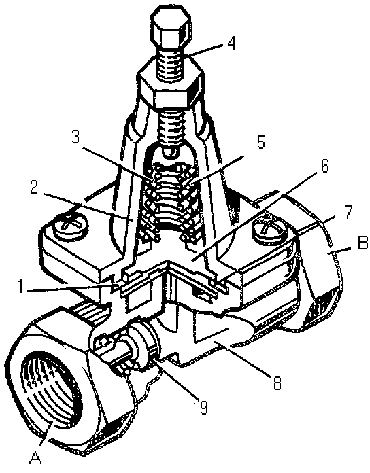

Single safety valve

Single safety valve is designed for isolating the circuits of the brake system from the circuit of the auxiliary consumers (traction frame latch), when the pressure in the receiver is less than 0.55 MPa (5.5 kgf/cm 2). The valve consists of body 8, cover 2, springs 3, 5, piston 6, diaphragm 7, non-return valve 9 and adjusting screw 4.

Cavity B of the valve is connected to the receiver. Cavity A is connected to the latch line.

When air is fed into cavity B, the compressed air through the duct enters under diaphragm 7. At a pressure exceeding 0.55-0.555 MPa (5.5-5.55 kgf/cm2 ), the diaphragm, in overcoming the spring tightening force, together with piston 6 rises and lets the compressed air flow through the duct into cavity A, thus depressing non-return valve 9, and further flows to the consumers.

At the compressed air pressure in the receiver below 0.55 MPa (5.5 kgf/cm 2) the piston under the action of the springs moves down, pressing diaphragm 7 to the central by-pass duct. The duct closes, disconnecting cavities B and A. Non-return valve 9 is pressed to the seat in the body. The non-return valve prevents air flow from cavity A into cavity B. The valve operating pressure is adjusted by screw 4.

1- gasket;

2- cover;

3,5- springs;

4- adjusting screw;

6- small piston;

7- diaphragm;

8- body;

9- valve