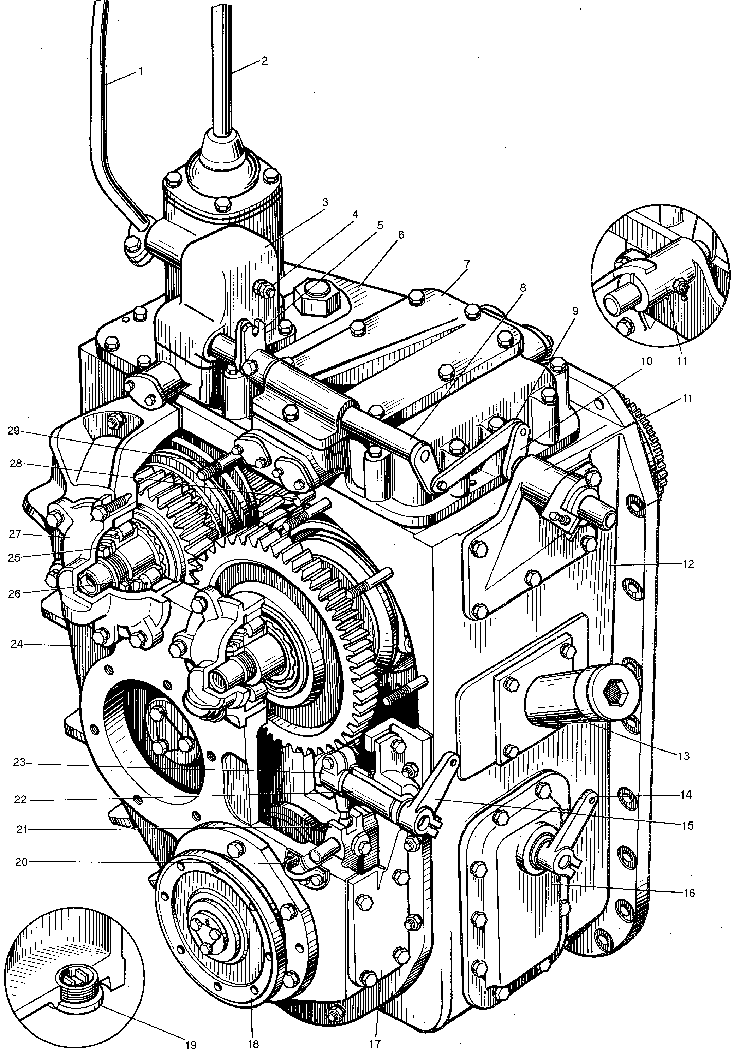

Gearbox of motor grader DZ-98B

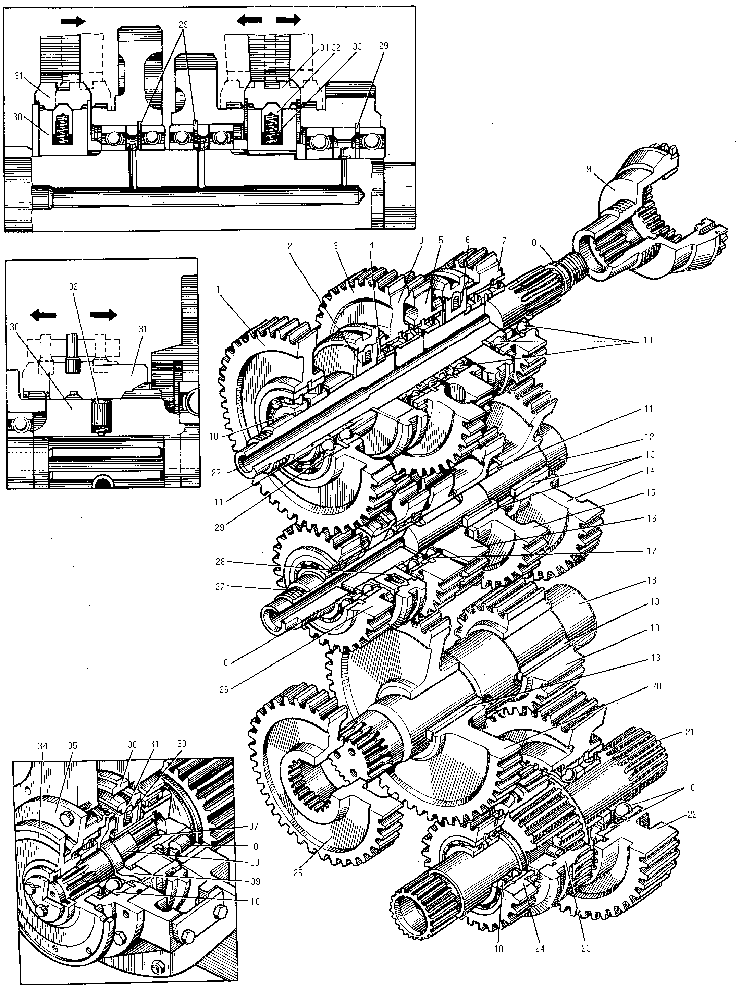

The gearbox featuring the constant meshing of gears is of a reversible type,i.e. it ensures forward and reverse travel in any gear, two-mode (working and transportation), three-speed (six gears altogether).The gearbox consists of a case and a cover machined jointly and hence not used separately, connected with the studs.Primary shaft 8 runs in two bearings, one of which is mounted in the case, while the other, in the cover.

The primary shaft mounts driving gears 3,5,7 of the third, second and first speed, respectively,having toothed rims, also reverse gear 1.

All the gears are mounted on ball bearings 10. Internal sleeves 2 and 6 rigidly attached on the shaft splines are mounted between the 1st and 2nd speed gears, also at the 3rd speed gear. External sleeves 31 are mounted on the splines of internal sleeves 2 and 6. Four cylindrical holes are made in the internal sleeves, to receive spring-loaded locks 32.

The locks thrust with their tapered surface against the tapered grooves of the external sleeves and ensure their locking in the neutral position.

The external sleves have the tapered slots on the teeth at the butt ends.The locks enter these slots when that or this gear is engaged.

The primary shaft has duct 27 for feeding lubricant to the bearings and a row of radial holes for each pair of bearings of the 1st, 2nd and 3rd gears, respectively.

The primary shaft is connected to the clutch cardan shaft through toothed flange 9. The second end of the primary shaft is closed with cover 27 having a hole for feeding lubricant. Reverse shaft 12 runs in two roller bearings. Driven gears 14,15 and 16 of the 1st, 2nd and 3rd gears, respectively,are rigidly secured on this shaft with the use of the sunk keys. All these gears are constantly meshed with the gears available on the primary shaft.

Gears 17 and 26 are mounted on the reverse shaft in the bearings. The sleeves similar to those located on the primary shaft are placed between them. Transmission of the torque through gear 17 ensures forward travel of the motor grader, while through gear 26, the reverse one, since the latter is in constant mesh with gear 1 on the primary shaft, while gear 1 in its turn,is in mesh with gear 25 on the layshaft.

The reverse shaft has an axial hole and a number of radial holes for feeding lubricant to the ball bearings the gears are mounted on. The bearings on which the reverse shaft runs are closed with the covers provided with lubricant intake. Layshaft 18 runs in two bearings.

Three gears are rigidly mounted on the shaft. Gear 19 ensuring the low gear (working mode) is fitted onto the shaft on a sunk key.

Gear 20 ensuring the high gear (transport mode) is also fitted onto the shaft on a sunk key. Gear 25 is fitted on the shaft splines and is in constant mesh with idle gear 1. Gear 20 is in constant mesh with gear 17 on the reverse shaft and at the same time with the gear on the step-up gear shaft. The layshaft is closed with the covers. Main shaft 21 runs in two roller bearings.Mounted on the shaft are two gears 22 and 24 which are in constant mesh with the corresponding gears on the layshaft.These gears run in ball bearings 10.Toothed sleeve 23 having internal splines and external teeth is spline-mounted between the gears.

The shaft splined portion has four cylindrical holes,which mount the spring-loated locks, unified with the locks on the primary shaft. Pinion-shaft 38 is mounted coaxially with the step-up gear shaft. It has the external teeth serving for engaging the front axle drive.The engagement is effected through the sleeves similar to those mounted on the reverse primary shaft.The internal sleeve is spline-mounted onto the step-up gear shaft.

Needle bearing 37 serves as a support for the pinion-shaft at one side and ball bearing 10 at the other side,the inner race of the bearing rests on pinion-shaft 38 of the front axle drive. The step-up gear shaft mounts toothed sleeve,through which the shaft is connected to the transfer reduction gear shaft.The bearings of the gearbox case are fitted into the special sleeves and covers.This precludes the hole for the bearing in the case and cover from wear and ensures better repairing ability of the case parts.