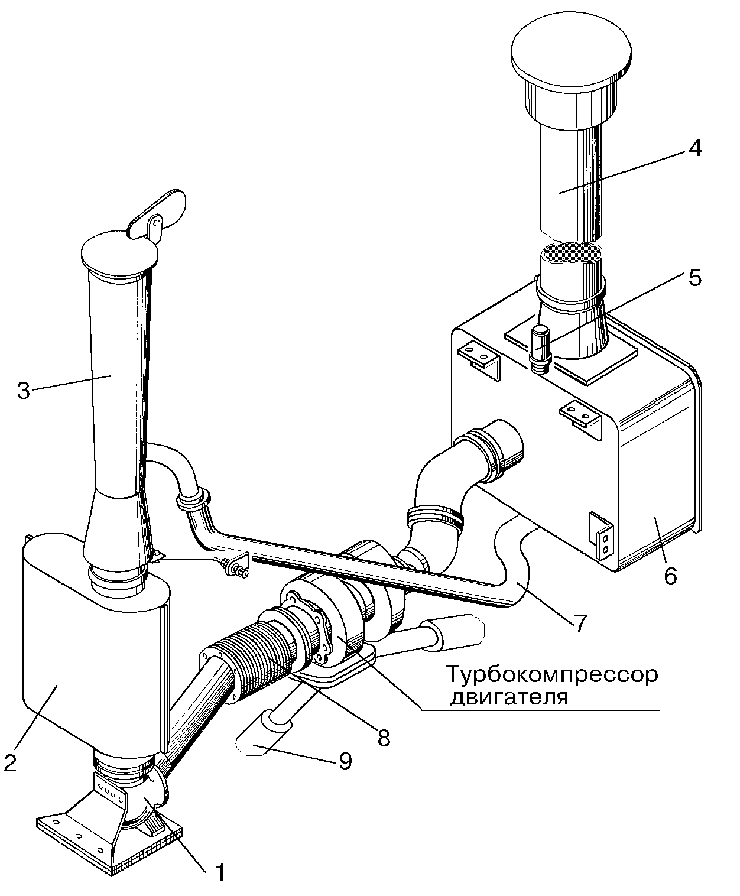

Suction and exhaust system of motor grader DZ-98B

The suction and exhaust system comprises an air cleaner 6, air intake pipe 4, ejector 3, silencer 2, clogging indicator 5 and connecting pipelines. Turbosupercharger of engine is brought into rotation by the energy of the engine exhaust gases. The turbosupercharger executes bleeding of atmospheric air througt an air cleaner and feeds air purified from dust under a pressure into the engine cylinders.

Turbosupercharger of engine is brought into rotation by the energy of the engine exhaust gases. The turbosupercharger executes bleeding of atmospheric air througt an air cleaner and feeds air purified from dust under a pressure into the engine cylinders.A turbosupercharger is absent in the YAMZ-240G engine.

The air cleaner 6 is connected to the air intake pipe 4 in one unit and is mounted on the motor grader hood. The air cleaner has two stage cleaning. Primarily air is cleaned in first stage by means of filters made of textile fabric,wherein the large dust particles are retained and at the cost of discharging produced by the exhausd ejector are exhausted and at the cost of discharging produced by the exhaust ejector are exhaused via pipeline and via ejector (where partially burned up) into the atmosphere.

Thus cleaned air enters second stage. Here the final filtration takes place in cassettes made of high-porous board. After that air is directed via pipeline into engine cylinders.

Clogging of an air cleaner 6 is checked by a clogging indicator 5, inside of which is placed a drum used as the alarm unit of indicator. A part of a side surface of the drum is red colour. When a permissible limit of air cleaner clogging is reached, the drum automatically turns and its red-colour part becomes visible in indicator window. Appearing of red colour in the indicator window means, that the second stage cassettes call for servicing.

Having performed the maintenance works of the second stage cassettes, reinstall the drum into its initial (working) position. In this case turn against the stop and then release the disc arranged in the upper part of the indicator according to the arrow.

If red colour of the drum is not disappeared in the indicator window after cleaning of the second stage cassettes, cleaning out the second stage filters made of textile fabric.

Important! The untight joints of the suction dust greatly reduce the service life of the engine.